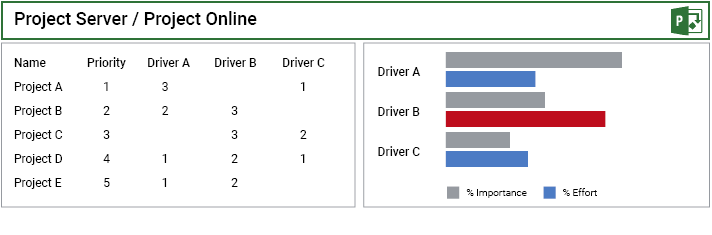

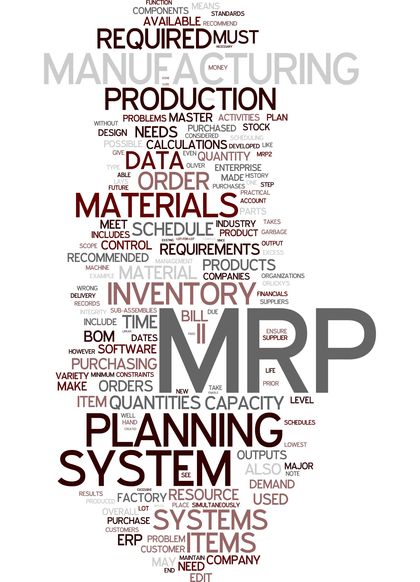

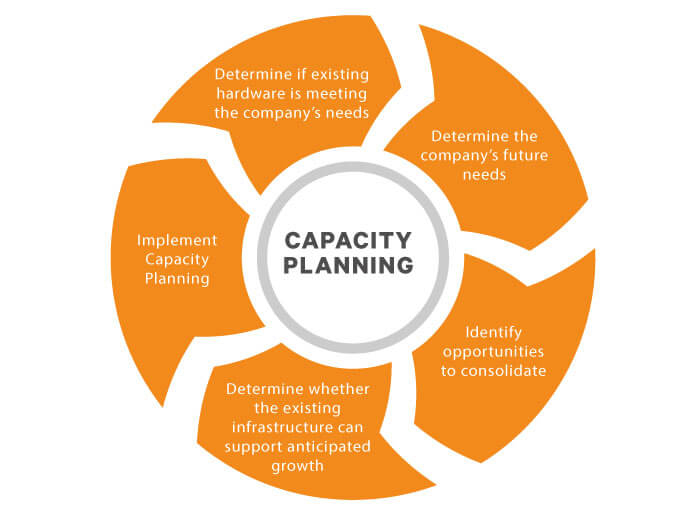

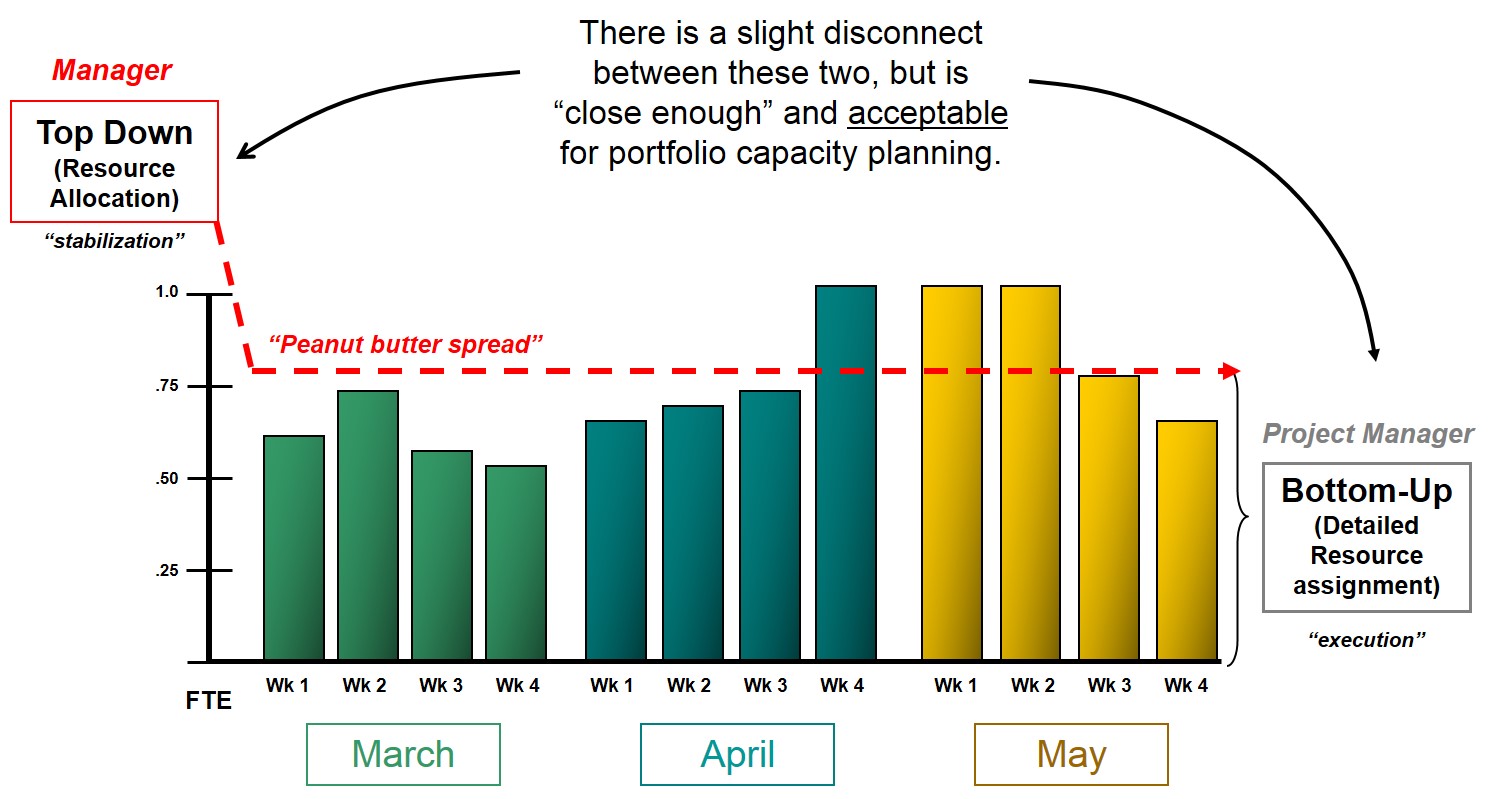

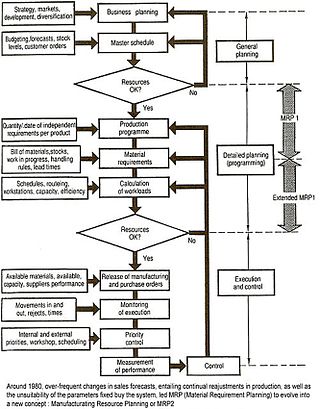

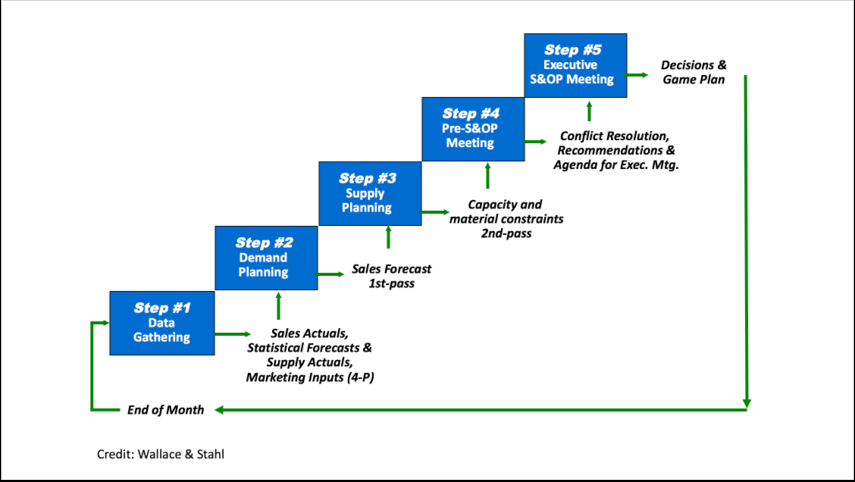

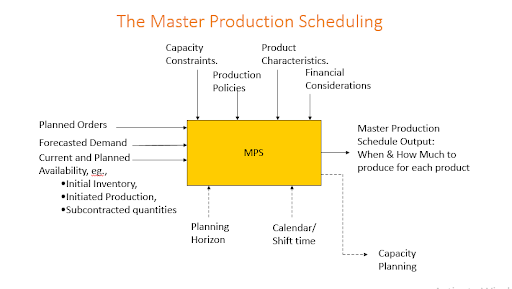

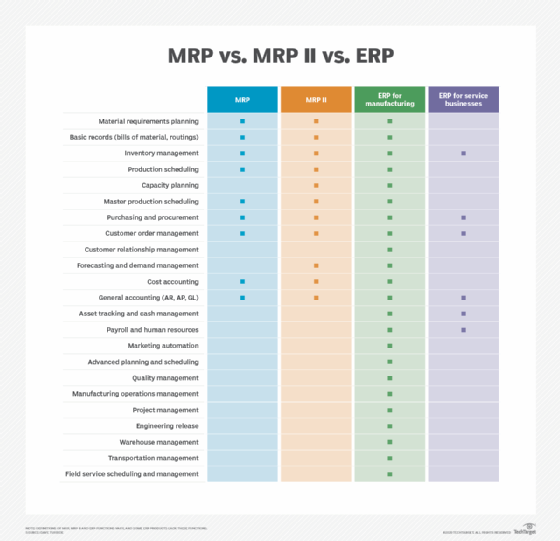

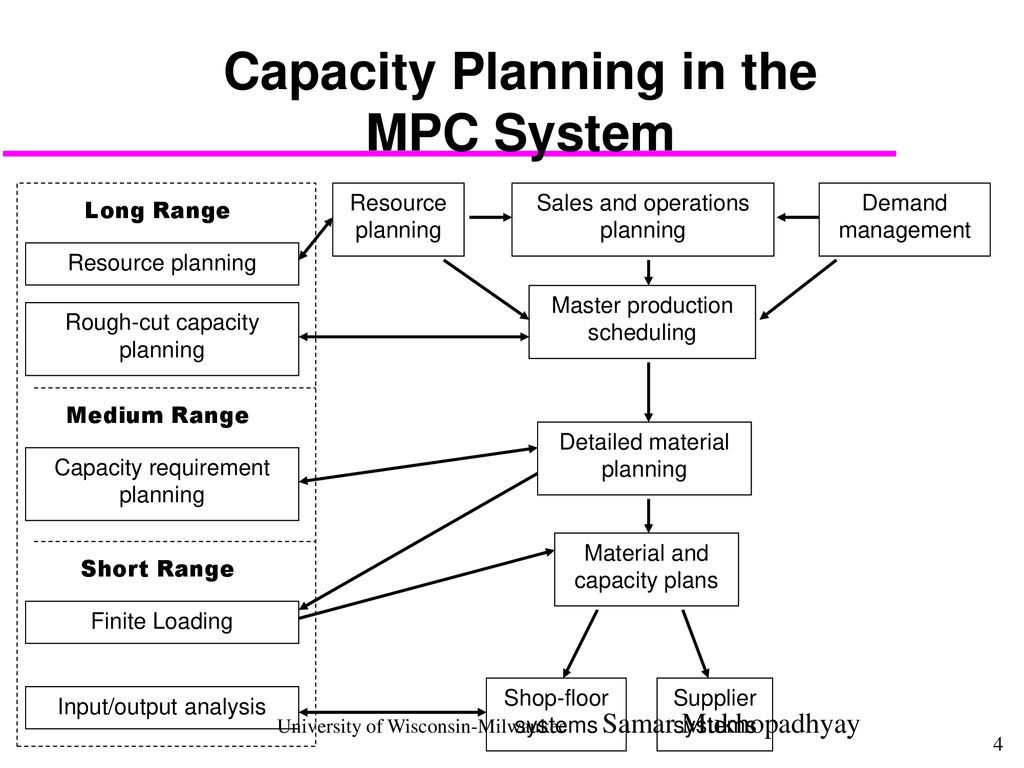

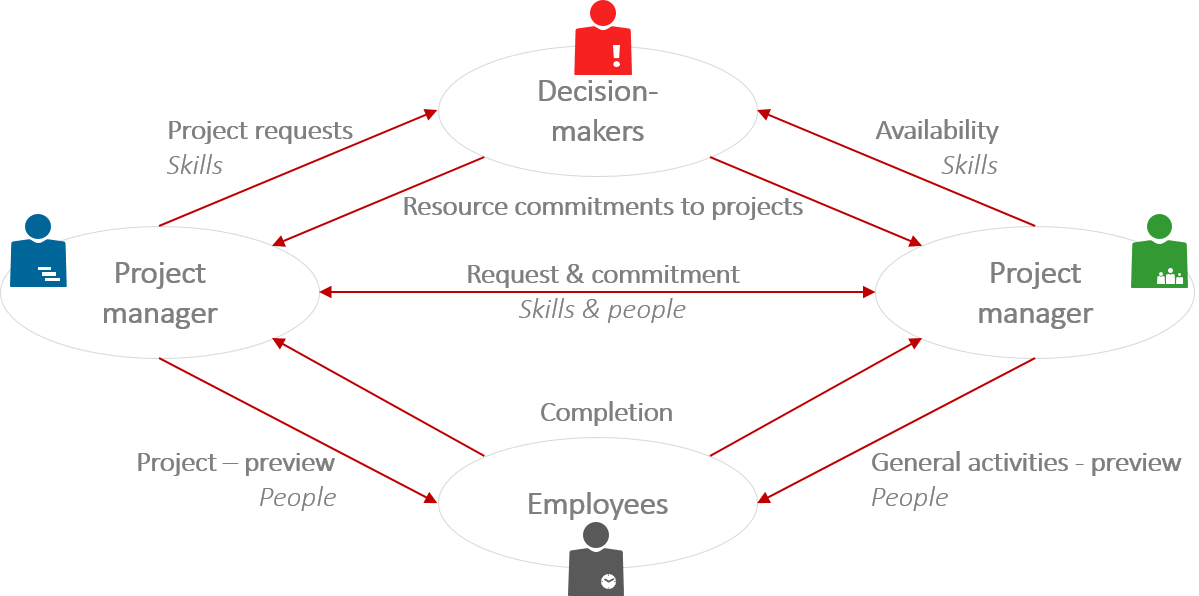

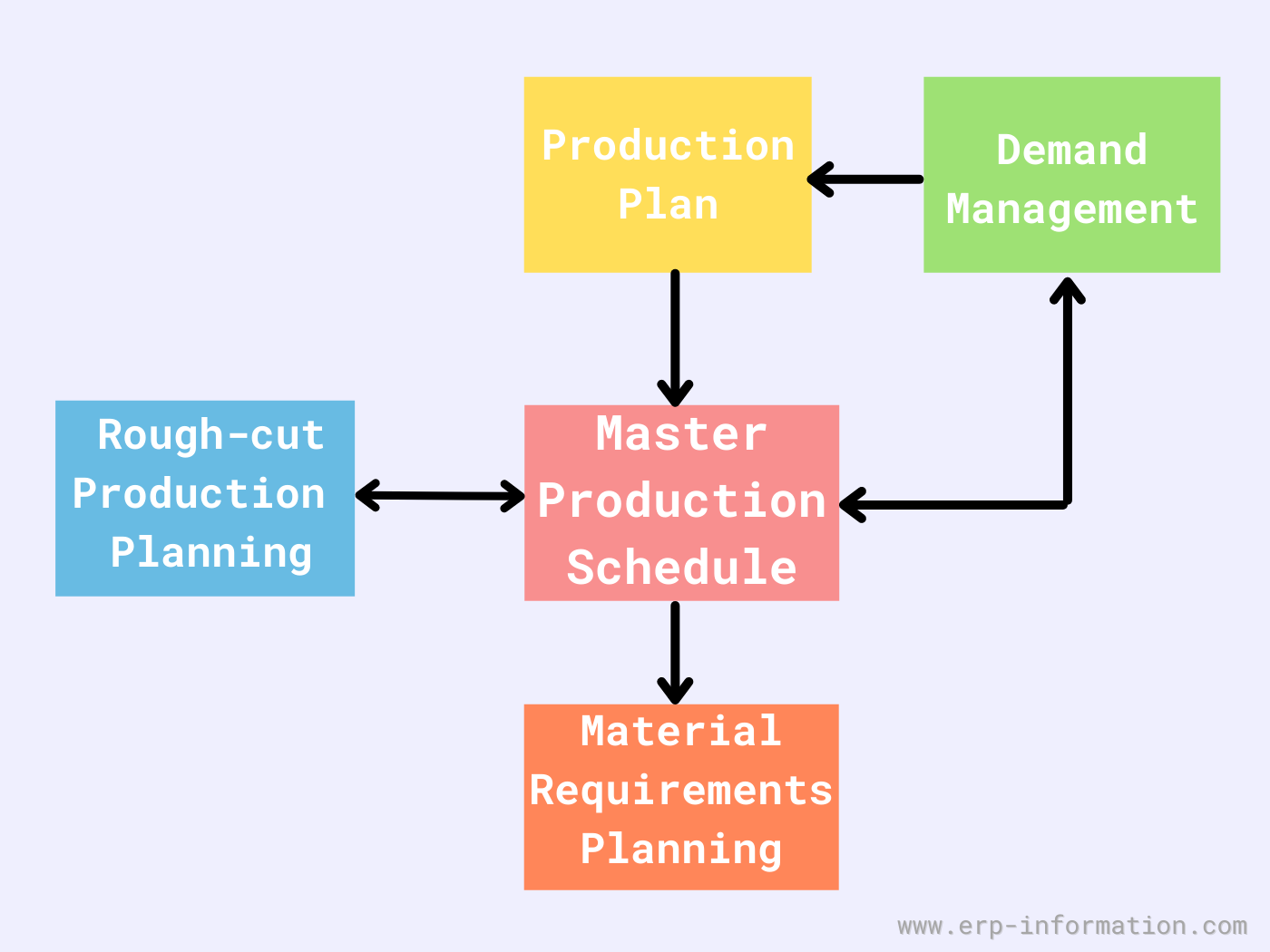

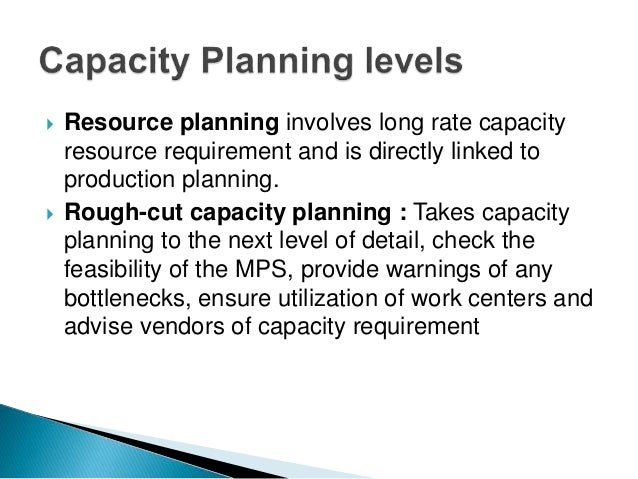

`RoughCut Capacity Planning (RCCP) at MPS level `feasibility `detailed capacity planning (CRP) at MRP level `both RCCP and CRP are only providing information Production Management 118 Master Production Scheduling MPS Product 1234 A 1000 1000 1000 1000 B 500 500 C 1500 1500 1500 1500 D 600 600 January Week Assembly Inspection 02As shown in Figure 1, different capacity planning methods are applied at different planning stagesFor example, resource requirements planning is generally used as a means of ensuring sufficient capacity to execute the sales and operations plan, and roughcut capacity planning deals with the capacity implications of the master production scheduleWhat is Capacity Planning?

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Level capacity strategy definition

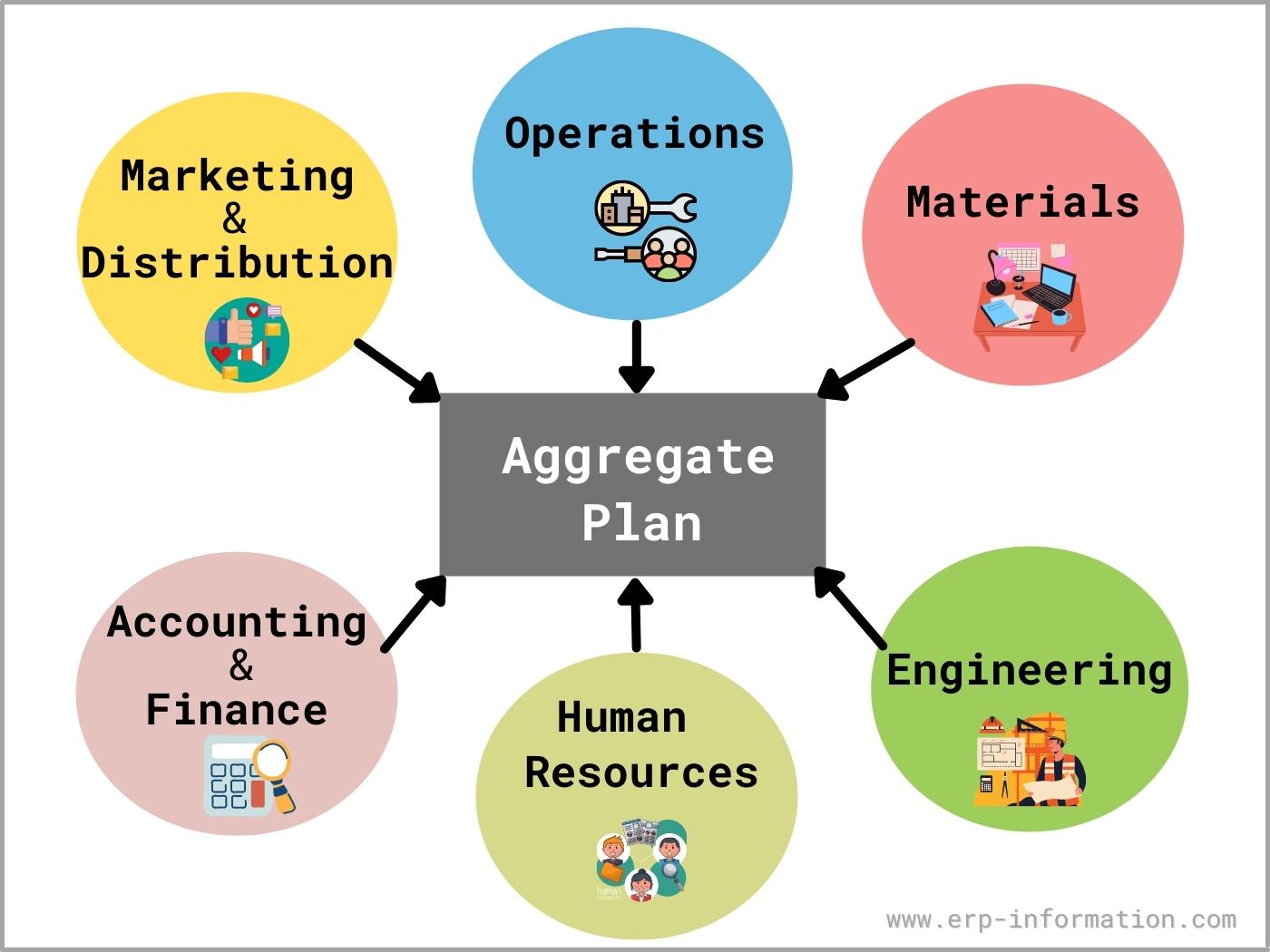

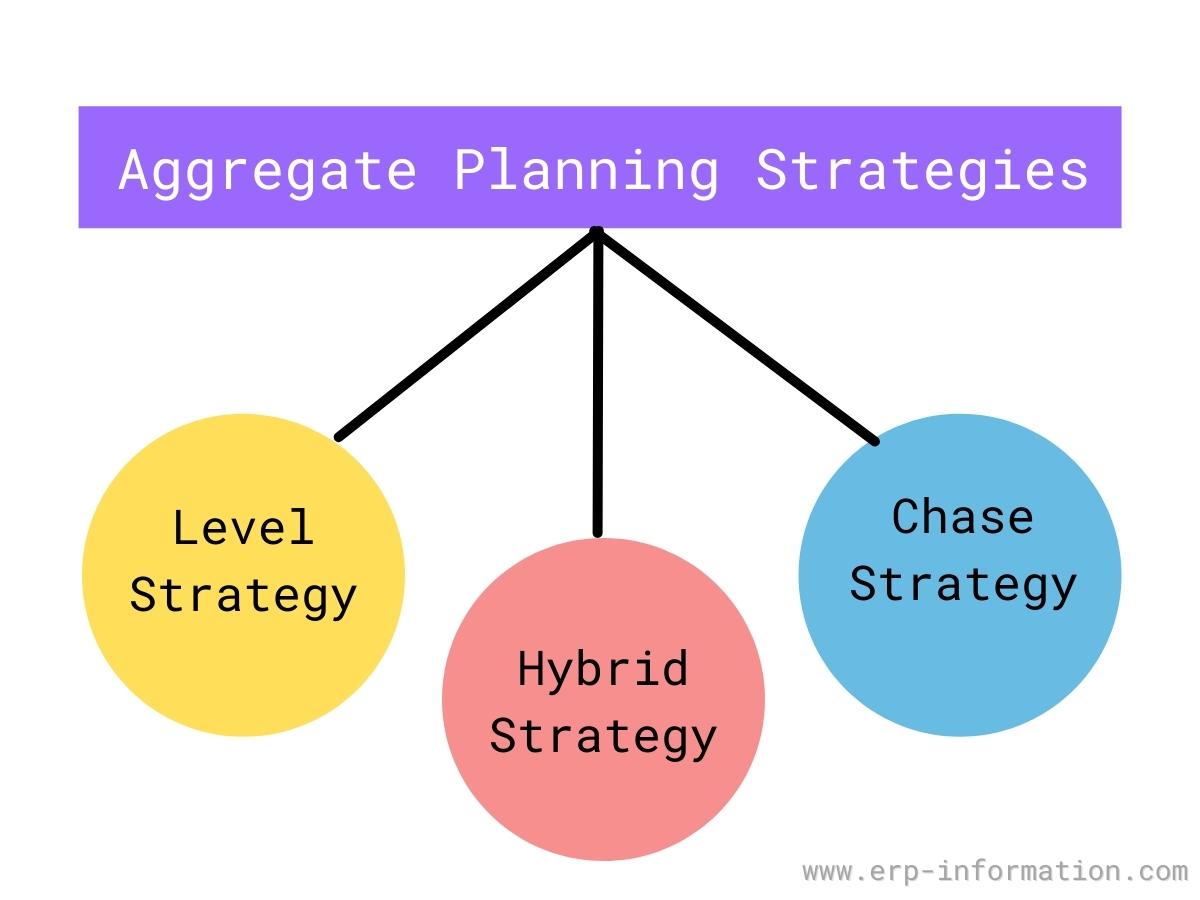

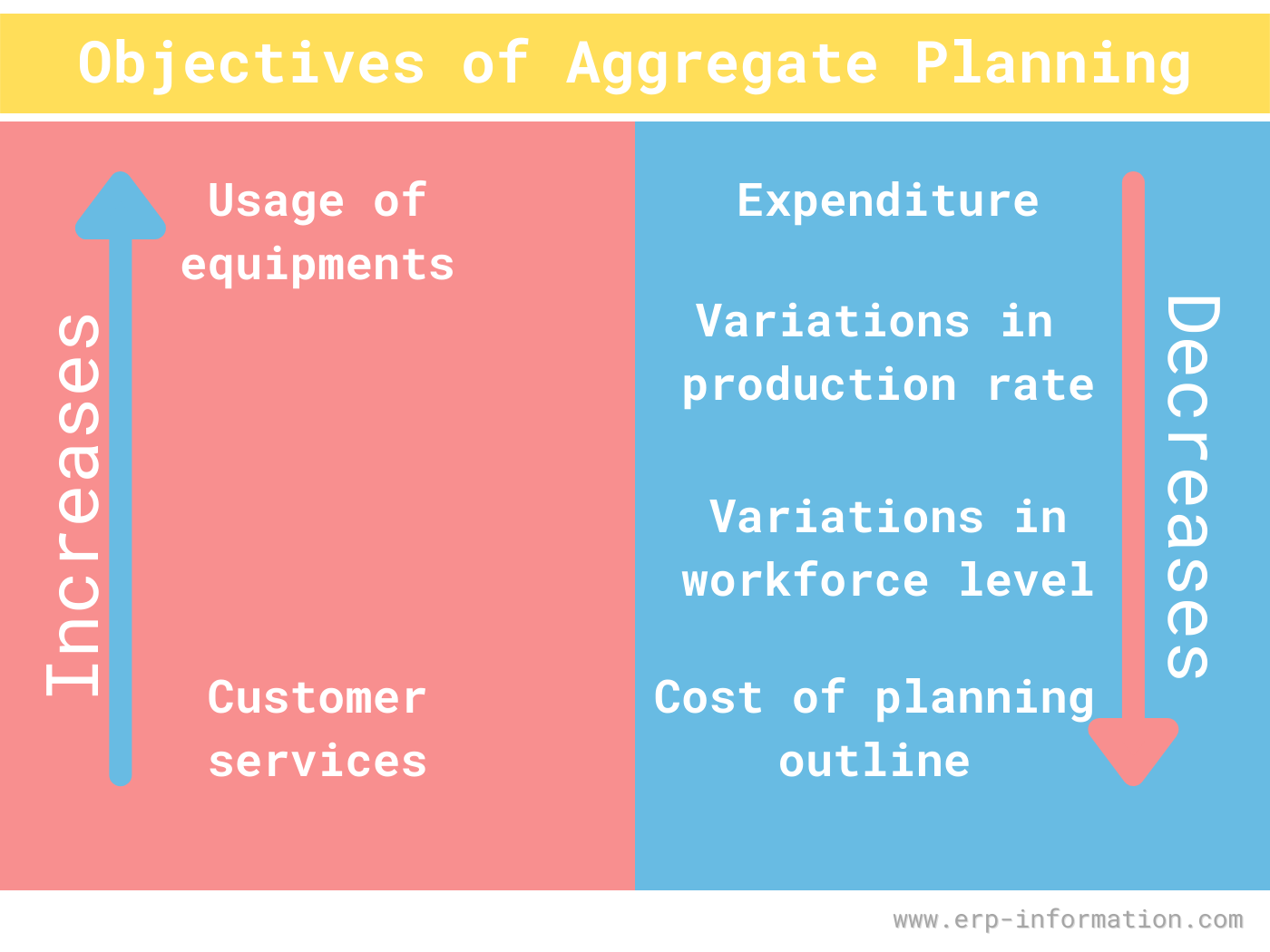

Level capacity strategy definition-選択した画像 level capacity Level capacity plan definition Total lung capacity, or TLC, refers to the maximum amount of air that your lungs can hold Typically, men have a greater lung capacity than women At rest a man's lungs can hold about 15 pints of air,Aggregate planning is the procedure of creating a production schedule for a given period It starts after listing out all the requirements that are crucial for uninterrupted production The usual planning horizon ranges from 3 to 12 months Word' aggregate' is derived from the Latin verb aggregate The meaning of it is 'add to' As far as resource planning is concerned BigPicture

Capacity Planning Meaning Classification And Its Goals

For you to commit to a sprint goal, you need to know current team capacity Team capacity is calculated as per people availability in that sprint Let's take an example Say team is of 5 people, then total capacity assuming 8 hour day, 2 weeks sprint (10 days) is = 5*8*10 = 400 hours Planning for this total capacity will be disasterPrePlanning Define network services, basic network configuration parameters Main planning Site survey, digital map, link budget, coverage plan, capacity plan Adjustment Drive tests, measurements, Display the signal level across the studied area PLANNING PHASES PLANNING PROCEDURES 8 Tools 50 Main Planning Tools • Aircom AssetLevel Capacity Plan Definition An approach to mediumterm capacity management that attempts to keep output from an operation or its capacity constant, irrespective of demand Operations Management by Nigel Slack, Alistair BrandonJones, Robert Johnston Level Capacity Plan Explanation

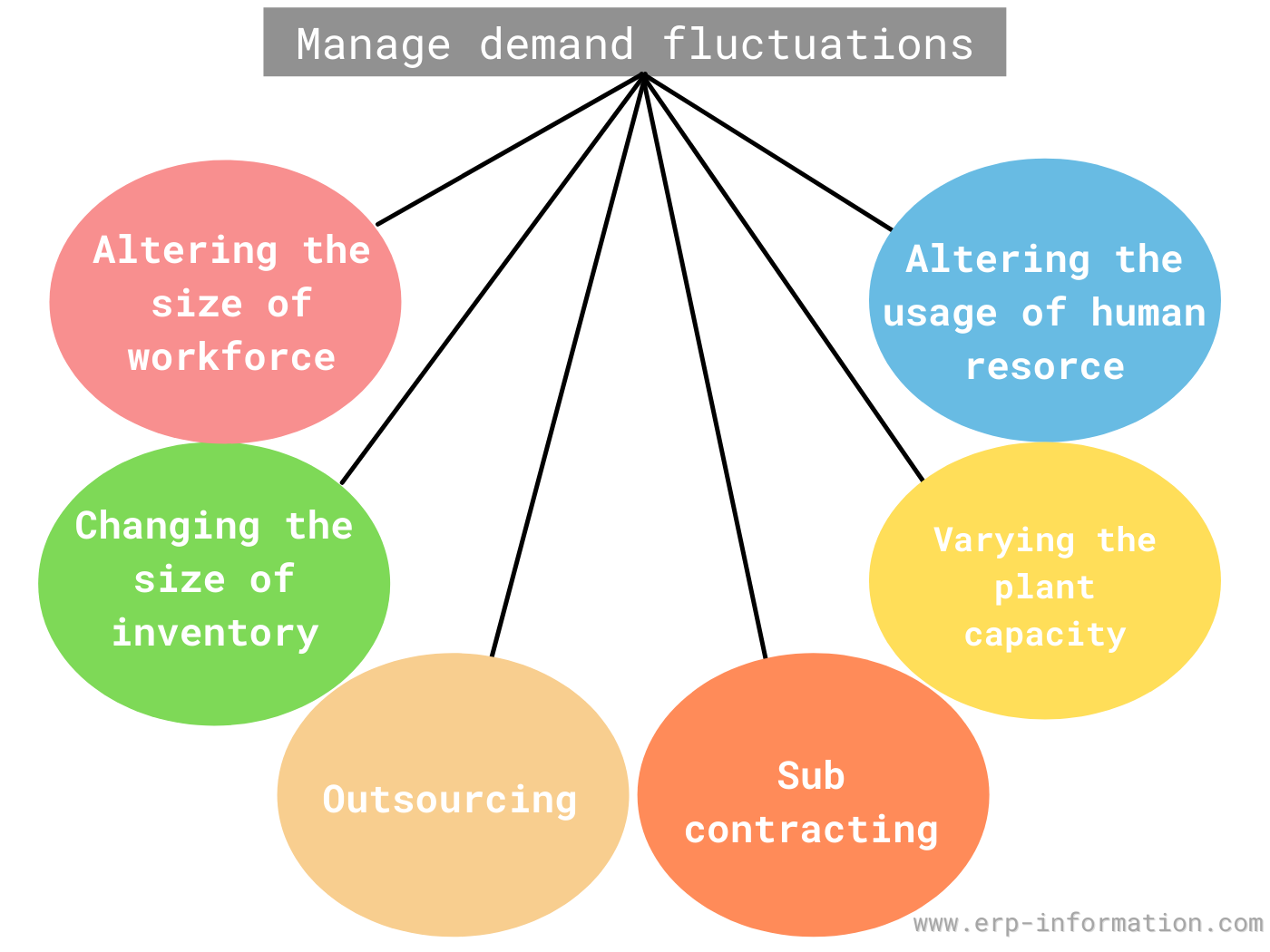

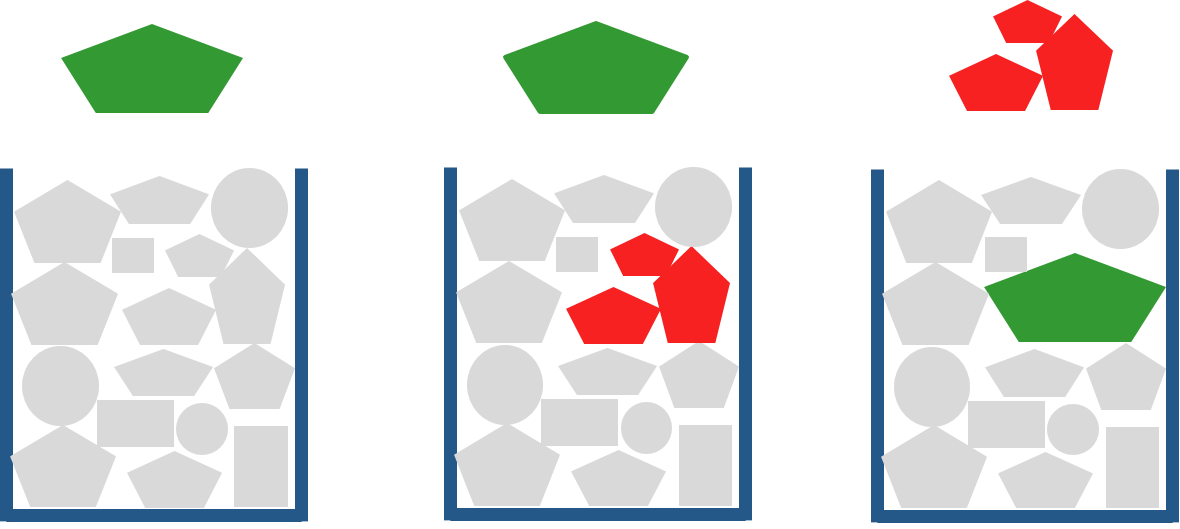

Level Capacity Plan The inventory size is varied keeping the workforce size and utilization of work constant The number of workers ( working size) is kept constant throughout the time period under consideration During months of low demand the excess units required over the units produced are taken from the inventory The objective of capacity management (ie, planning and control of capacity) is to match the level of operations to the level of demand Capacity planning in Production and Operation Management Capacity planning is to be carried out keeping in mind future growth and expansion plans, market trends, sales forecasting, etc What is Capacity Planning Strategy?

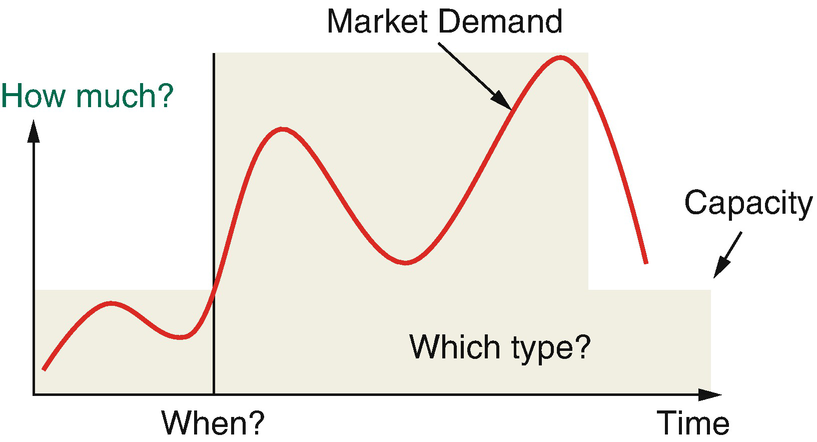

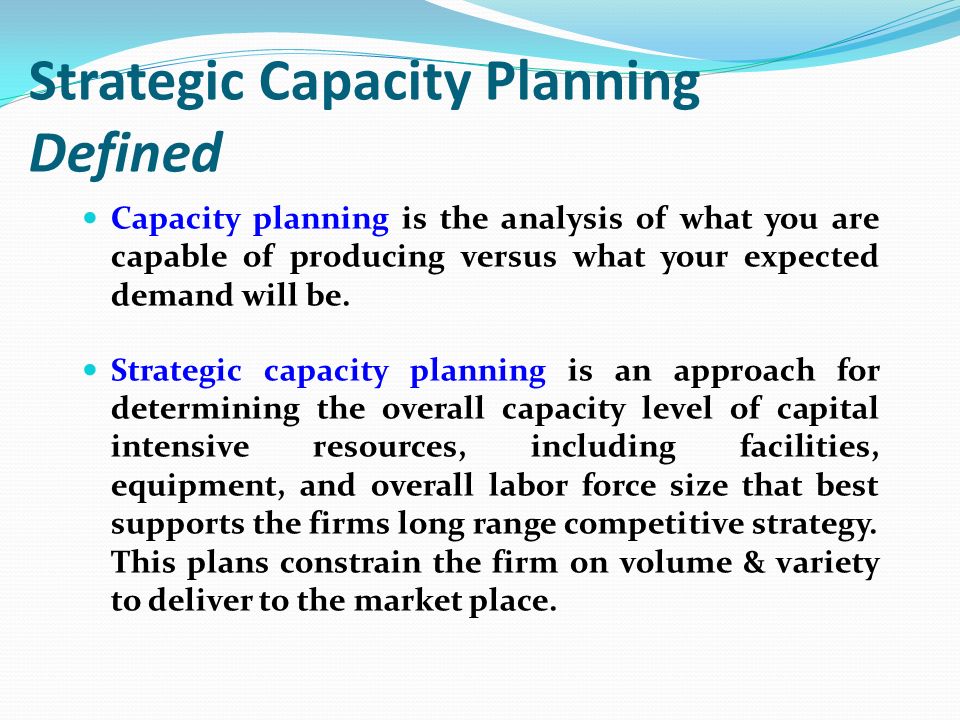

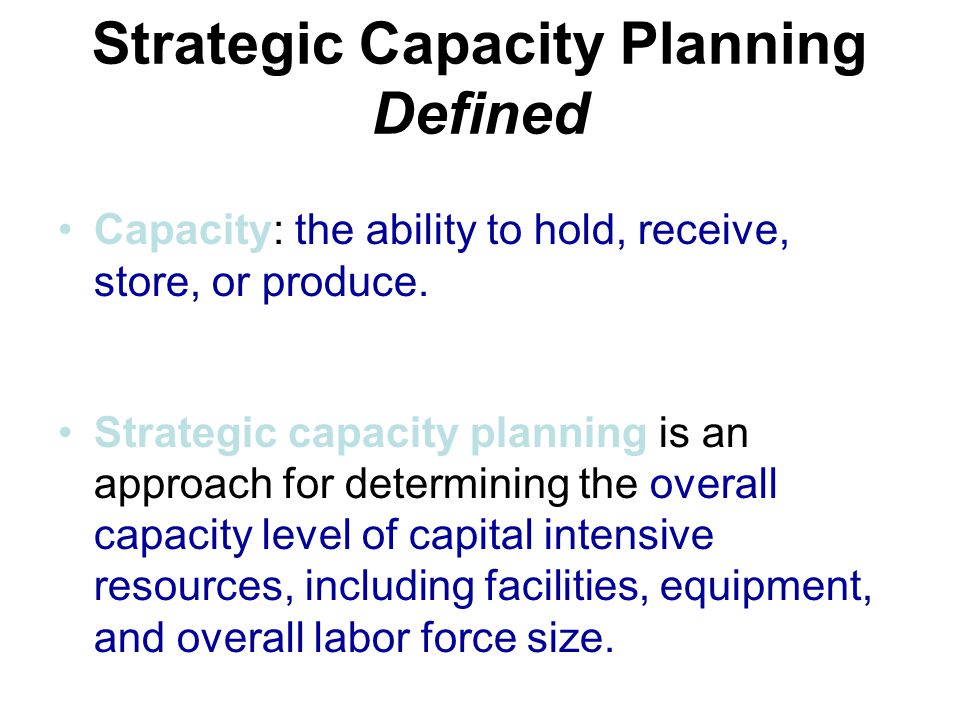

A period's planned quantity of output is equal to that period's expected demand Level capacity strategy When an organization adopts the level capacity strategy then it manufactures at a constant output rate It does not consider any fluctuation or change in the level of demandStrategic capacity planning is utilized for capital intensive resource like plant, machinery, labor, etc Strategic capacity planning is essential as it helps the organization in meeting the future requirements of the organization Planning ensures that operating cost are maintained at a minimum possible level without affecting the quality It ensures the organization remain competitive andCapacity planning apacity refers to an upper limit or ceiling on the load that an operating unit can handle while capacity planning is a key strategic component in designing a system (Stevenson, 09) It encompasses many basis decisions with longterm consequences for the C Author's , 1 Dept of Bus Admin, Faculty of Mgt Sci, Kogi State

Capacity Planning Everything You Need To Know Opensense Labs

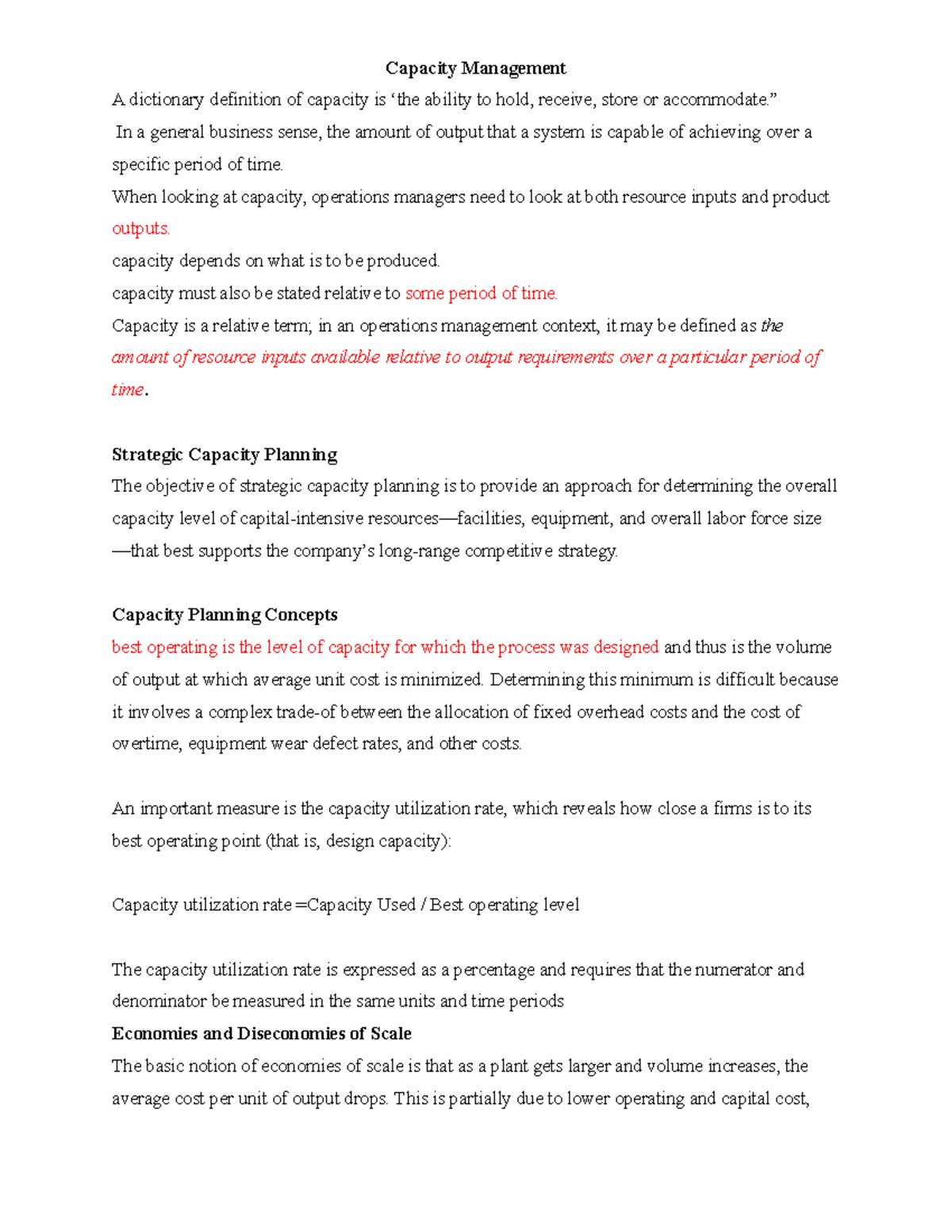

Capacity Management Lecture Note Capacity Management A Dictionary Definition Of Capacity Is The Studocu

Data center capacity planning is the process of planning for current and future hardware, software and other data center infrastructure requirements within a perceived time frame It is a form of IT capacity planning that reviews and analyzes current data center utilization in order to plan ahead for data center capacity increment, decrement,Capacity planning strategy involves the process used to determine the resources manufacturers need to meet the demand for their products or services The level of capacity directly relates to the amount of output in the form of goods and services manufacturers can produce to satisfy customer demand Capacity planning is the process used by a business to determine the resources it will acquire to meet the demand for its products or services The more capacity a company has, the more output in

Study Of Manufacturing System Capacity Planning Control Steps In Capacity Planning Measuring Demand Capacity Yield Management

What Is Capacity Management Definition And Faqs Omnisci

Capacity requirements planning has both long and shortterm implications for a firm's success In the short term, monthly and quarterly sales numbers are heavily affected by whether the company capacity planning In information technology, capacity planning is the science and art of estimating the space, computer hardware, software and connection infrastructure resources that will be needed over some future period of time A typical capacity concern of many enterprises is whether resources will be in place to handle an increasingResource capacity planning is a tool used to determine the resources needed by an organization in order to meet future workflow demands that stem from the need to increase capacity or a move to a new system, workflow or business process It requires determining the required resources for current workflows and processes and comparing that to the

Difference Between Resource Planning And Capacity Planning

How To Do Capacity Planning Youtube

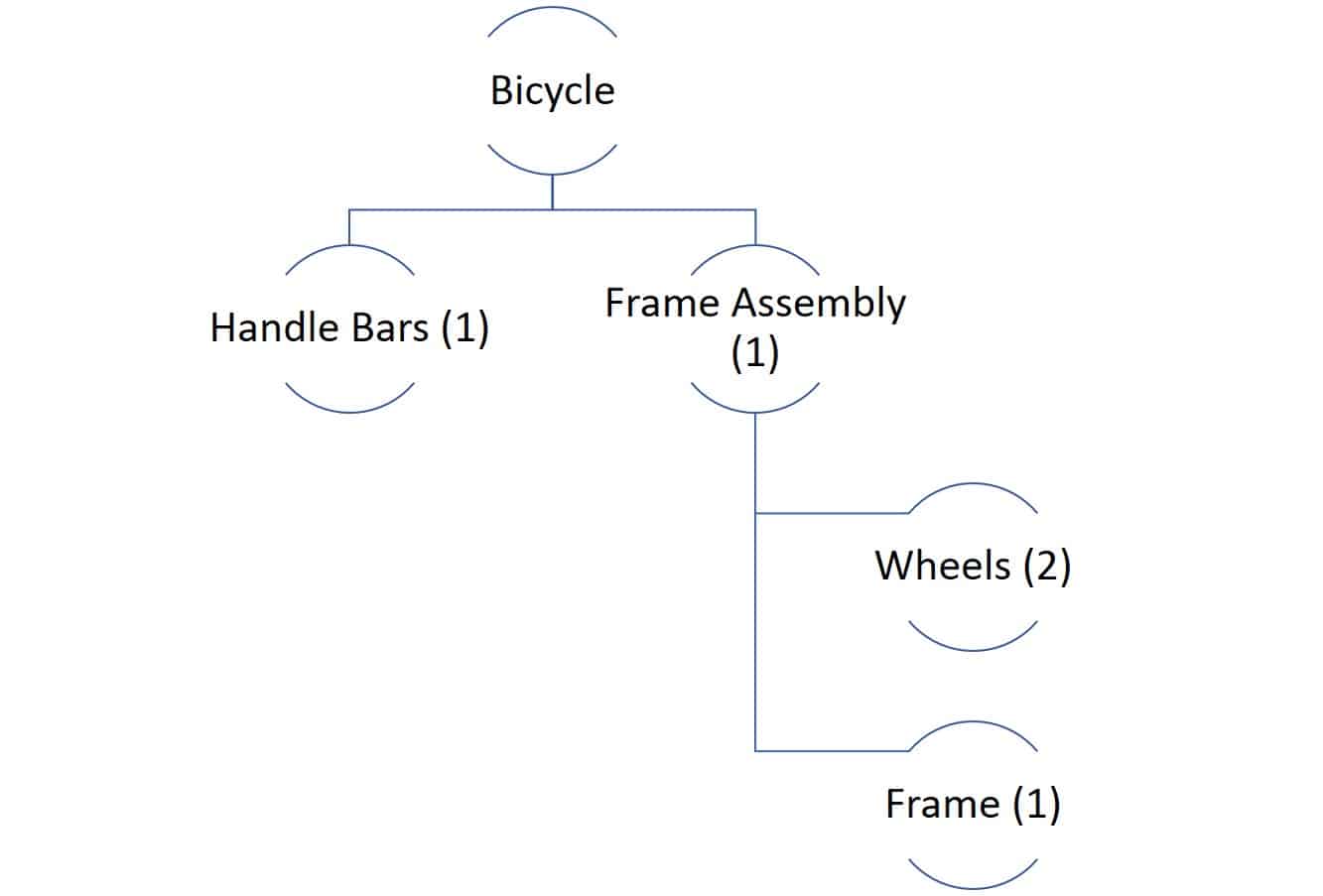

Practical examples of models in capacity planning for different production modes include 1 Make to Stock (MTS) Make to Stock is common within discreet manufacturing and process manufacturing As these operations often have complex multilevel BOMs, capacity planning must include planning for subprocesses required to produce componentsCapacity planning is longterm decision that establishes a firm's overall level resources It extends over a time horizon long enough to obtain resources Capacity decisions affect the production lead time, customer responsiveness, operating cost and company ability to competeCapacity Planning Capacity Planning or Aggregate Planning is defined as the process of aggregating (ie, consolidating or grouping) all the requirements for fulfilling capacity requirements for each period in the intermediate horizon and determining the best way to provide the needed capacity The objectives of capacity planning are

Achieving High Performance Low Cost Logistics Kearney

Capacity Planning Strategies Benefits And Best Practices

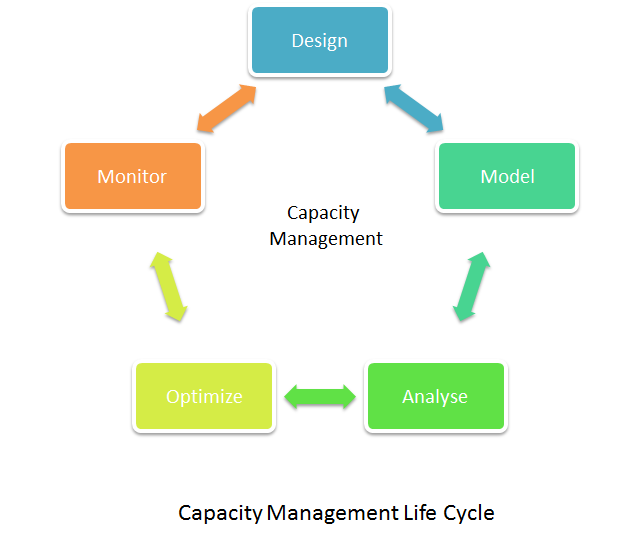

Overview of Rough Cut Capacity Planning (RCCP) RCCP verifies that you have sufficient capacity available to meet the capacity requirements for your master schedules RCCP is a longterm plan capacity planning tool that marketing and production use to balance required and available capacity, and to negotiate changes to the master schedule and/or available capacity1 Capacity decisions have a real impact on the ability of the organizationto meet future demands for products and services 2 Capacity decisions affect operating costs 3 Capacity is usually a major determinant of initial cost Typically, the greater the capacity of aCapacity Management Definition Capacity management refers to the wide variety of planning actions used to ensure that a business infrastructure has adequate resources to maximize its potential activities and production output under any condition

A Roadmap To Success In Capacity Management

Introduction To Sap Pp Production Planning

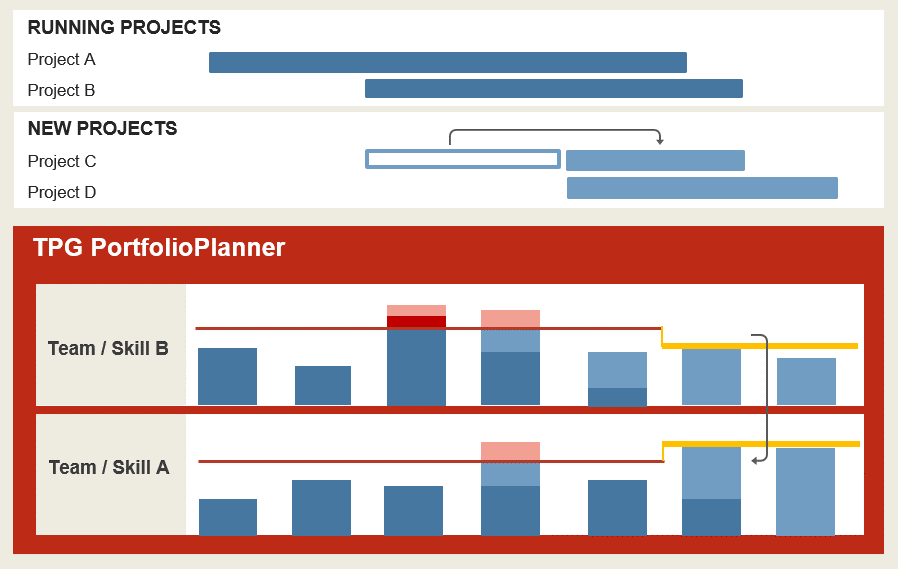

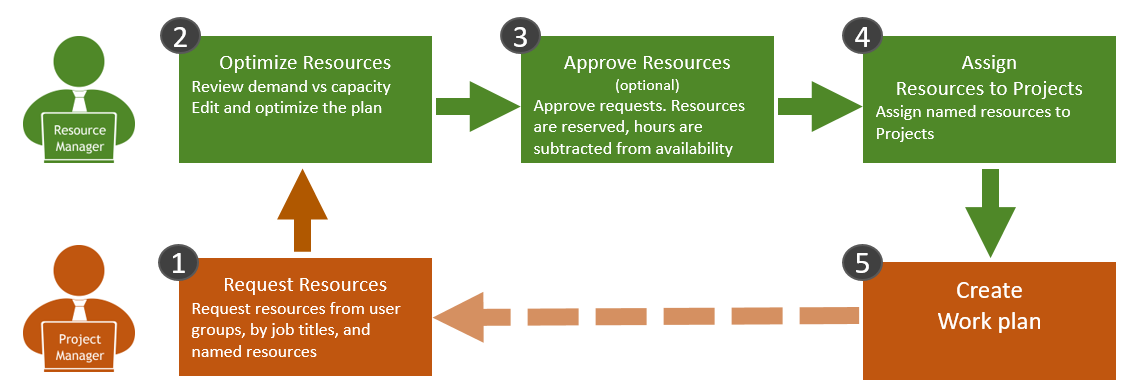

Capacity planning is high level and strategic To keep your capacity planning simple, you need to analyze your capacity plan at the team or skill level and not by analyzing individual resources Which means for example comparing how many project managers you need for your projects vs how many you currently haveDefinition The Capacity Plan is used to manage the resources required to deliver IT services The plan contains scenarios for different predictions of business demand, and options with cost estimates to deliver the agreed service level targetsCapacity is the maximum amount of work an accounting practice is capable of completing in a given period of time Capacity planning is the process of determining the resources (time, people, etc) that the firm needs to meet changing demands for its services – in other words, how it will meet its current and future client needs

Itil Service Management Itil Management Project Management Project Management Templates Task Management

Study Of Manufacturing System Capacity Planning Control Steps In Capacity Planning Measuring Demand Capacity Yield Management

Capacity planning is defined as a method to gauge the production capacity needed to meet the changing product demands of an organization Two terms of design capacity and effective capacity are used extensively in the context of capacity planning The first is the maximum work that is completed in a specific period by an organization, and the latter is the The first step in doing so, however, is to distinguish surge capacity from surge capability 111 Medical Surge Capacity Medical surge capacity refers to the ability to evaluate and care for a markedly increased volume of patients—one that challenges or exceeds normal operating capacityCapacity are interdependent, and growth in one area is dependent on growth in another16 Consequently, while a particular capacitybuilding initiative might focus on one type of capacity, all four types of capacity must be "aligned and addressed" if the organization is to meet its goals for change17 Levels of capacity

Capacity Planning Strategies Benefits And Best Practices

Capacity Management Objectives Roles Concepts Mitsm

Capacity planning and control is the task of setting the effective capacity of the operation so that it can respond to the demands placed upon itThis Product capacity planning Product capacity planning ensures that you always have enough raw materials and products needed to complete an order Raw material management is key to product capacity planning, and multi level bill of materials (BOM) are especially important if your products require a lot of product variants and subassemblies Capacity is the maximum level of output that a company can sustain to make a product or provide a service Planning for capacity requires management to accept limitations on the production process

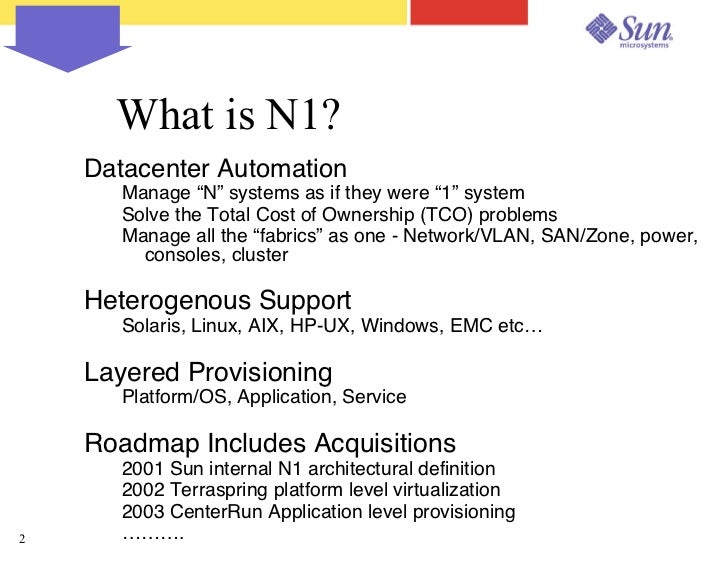

Capacity Planning For Virtualized Datacenters Sun Network 03

Capacity Planning In Project Management 4 Vital Success Factors Update 21

The level capacity strategy involves maintaining stable workforce level and output rates over the planning horizon This allows the firm to maintain inventory levels of finished products higher than expected in situationsIt needs to balance its assets and plan accordingly It is a model that targets establishing a computational relationship between production designs, process sheets, consumption of raw materials, time available, labor availability, and so on Types of capacity planning In the case of capacity planning, it needs lots of considerationLead capacity planning is the most radical of the capacity planning strategies, as it involves changing capacity in anticipation of market demand Hiring can be a slow process, and lead capacity planning allows organizations to prepare for growing or rapidly evolving markets

Automotiveip Co Uk

Capacity Planning Springerlink

And the third level of capacity planning, capacity requirements planning, occurs at this point This capacity check looks at all resource capacities, not just bottlenecks The result of this process is a finalized material requirements plan The bottom level is where planning ends and execution takes over The materialThen, in our capacity plan, we would want to subtract 42% of our calls from the 'Offered call volume' forecast to drive the number of expected transactions in our CP Model That is how many calls we would expect 'not to process' if we were properly staffed to meet service levelCapacity Planning refers to the arrangement in which organizations or teams match employees together with the needs of a project Capacity is the optimum level of work that can be done within an established period Usually, it is measured in the quantity of work that is carried out by employees

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

/nissan-expands-production-capacity-at-iwaki-plant-72515647-5b009db3312834003775dbb0.jpg)

Capacity Requirements Planning Crp Definition

Capacity planning is a type of production planning that involves determining production capacity and workforce needs to make sure your supply chain is equipped to meet demand Capacity planning lets businesses know how and when to scale, identify bottlenecks, create better design capacity, and mitigate risk, within a planned period of timeRough Cut Capacity Planning (RCCP) Rough cut capacity planning (RCCP) involves planning capacities at key / bottleneck work centers and broadly balancing workloads It thus validates the MPS Material requirements planning (MRP) uses a master production schedule (MPS) of end items to determine the quantity and timing of component part productionLevels,"3 equivalent to measuring baselines and the progress of (capacity) development indicators Capacities can be grouped in three levels individual, organizational and enabling environment, which altogether are interdependent and mutually reinforcing (see Figure 1) Figure 1 Three interconnected levels of capacity _____

Define Capacity Explain What Is Meant By Capacity Planning

What Is Aggregate Planning 3 Strategies And Examples

Simply put, if capacity is the means to plan and achieve, then capacity development describes the ways to those means An essential ingredient in the UNDP capacity development approach is transformation For an activity to meet the standard of capacity development as practiced and promoted by UNDP, it must bring about transformation that is Definition 1Monitor output 2Compare it with the plan 3Taking corrective actions Term 2 Major components in defining capacity are Definition 1The capability of a system to perform its expected function 2The capability of a worker, mashine, work cener or organisation as measured in output per time period

Capacity Planning Everything You Need To Know Opensense Labs

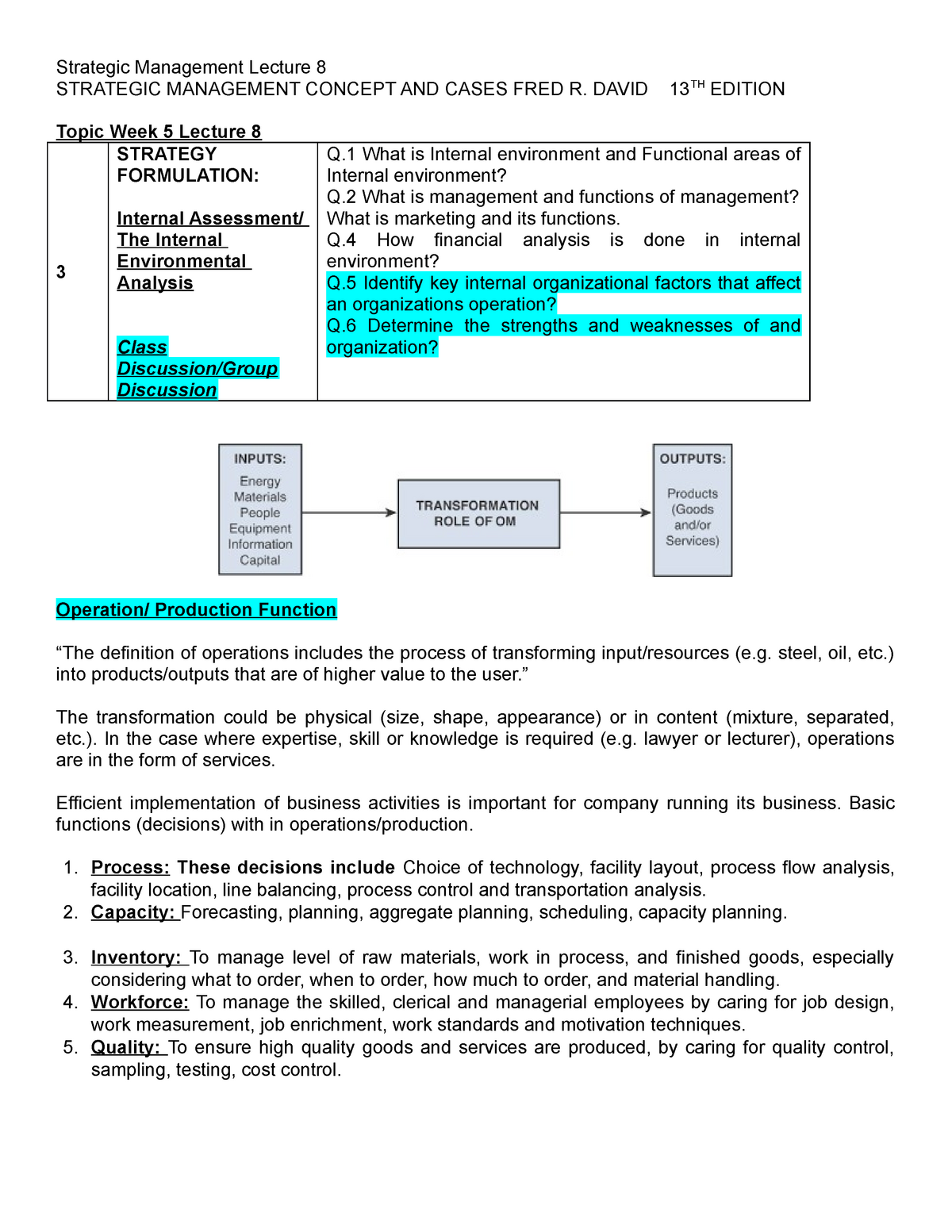

Strategic Managemetn Lecture 8 Probability For Engineers Eee324 Studocu

Everything You Need To Know About Material Requirements Planning Mrp Smartsheet

Capacity Planning How Much Long Range Capacity Is Needed When More Capacity Is Needed Where Facilities Should Be Located Location How Facilities Should Ppt Download

Production Planning Meaning Importance Steps Example Mba Skool

Capacity Management Archives Ppmexecution Com

Capacity Planning Meaning Classification And Its Goals

Operations Management Daniel S Blog

Iteration Planning Scaled Agile Framework

Operations Management Wikipedia

Capacity Planning Meaning Strategies Importance And Procedure

Capacity Planning Everything You Need To Know Opensense Labs

Capacity Utilization Definition Example And Economic Significance

What Is Aggregate Planning 3 Strategies And Examples

Capacity Planning Strategy Requirements Demand Steps Powerpoint Presentation Pictures Ppt Slide Template Ppt Examples Professional

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Capacity Planning An Overview Sciencedirect Topics

Dom 511 Operations Management Practice Ppt Video Online Download

Simple Powerful Resource Management Smartsheet

Business Capability Map And Model The Definitive Guide Leanix

Capacity Planning For Internet Services Pdf Free Download

Capacity Planning

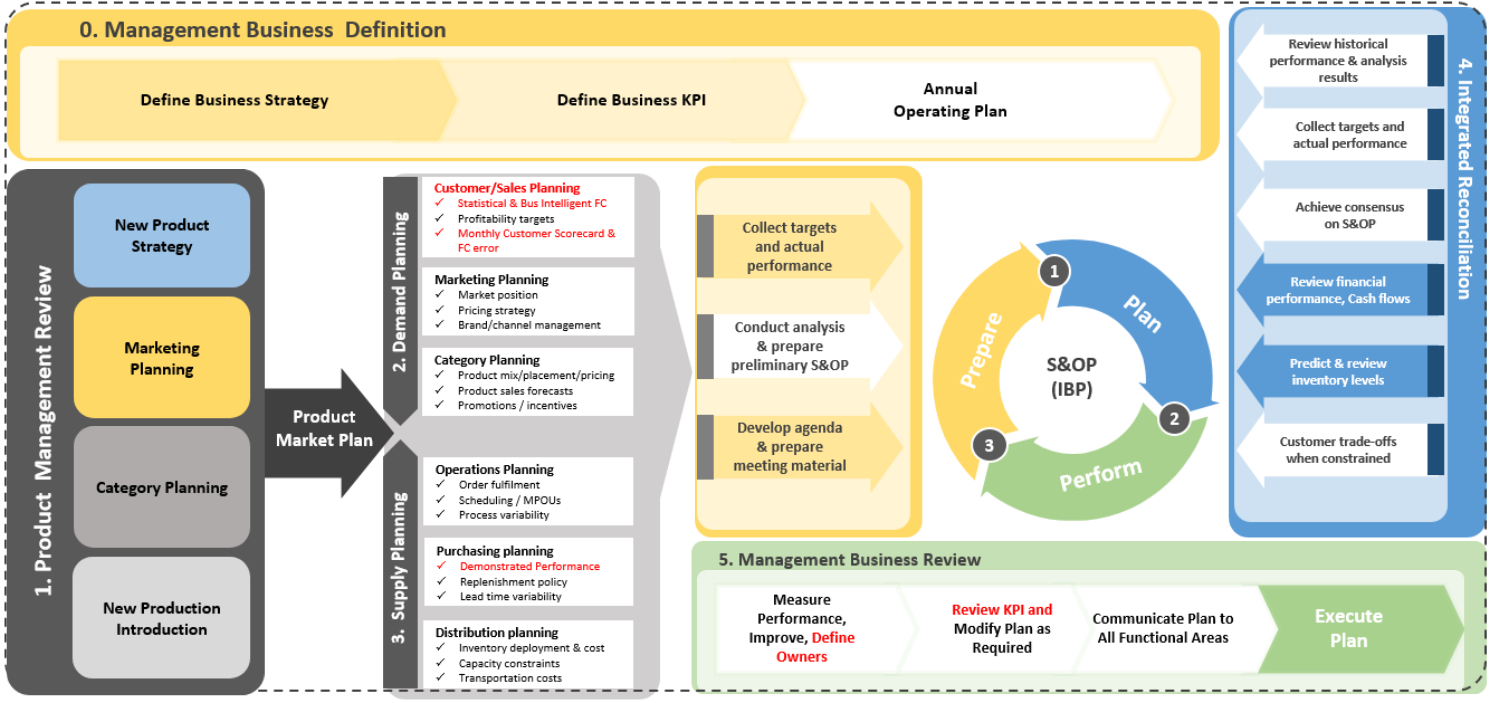

Ready To Upgrade Your S Op Process For Industry 4 0

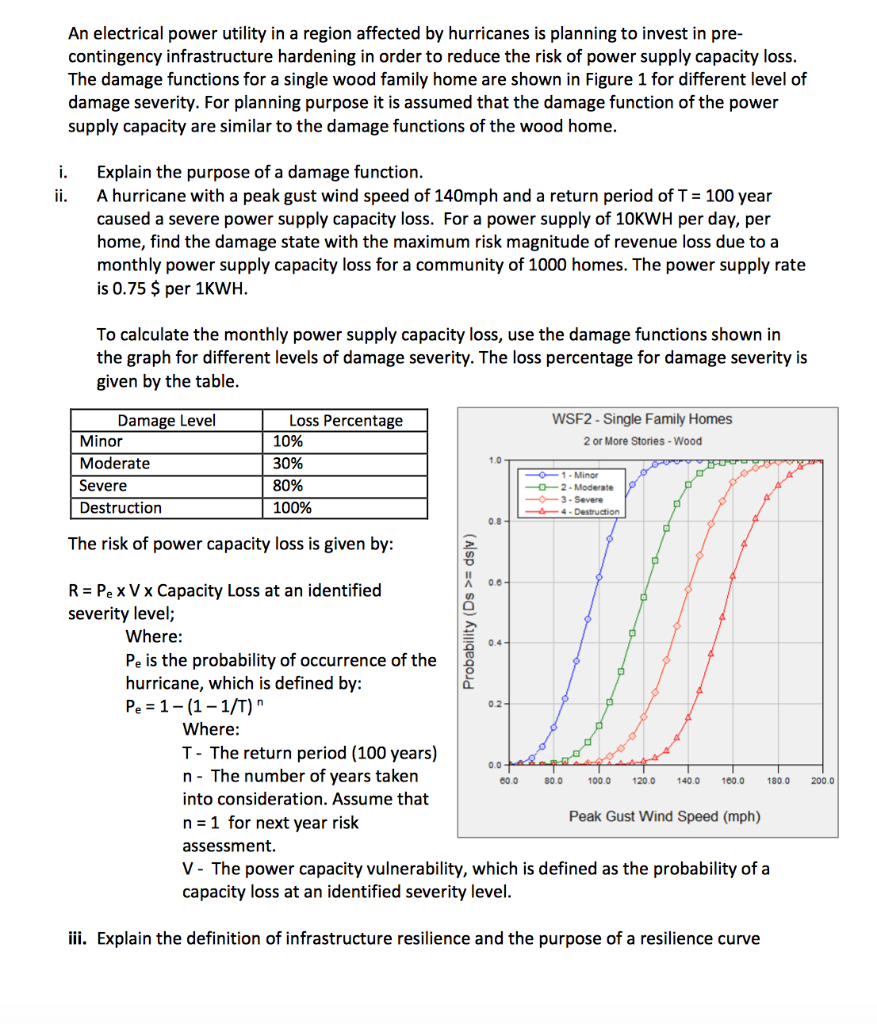

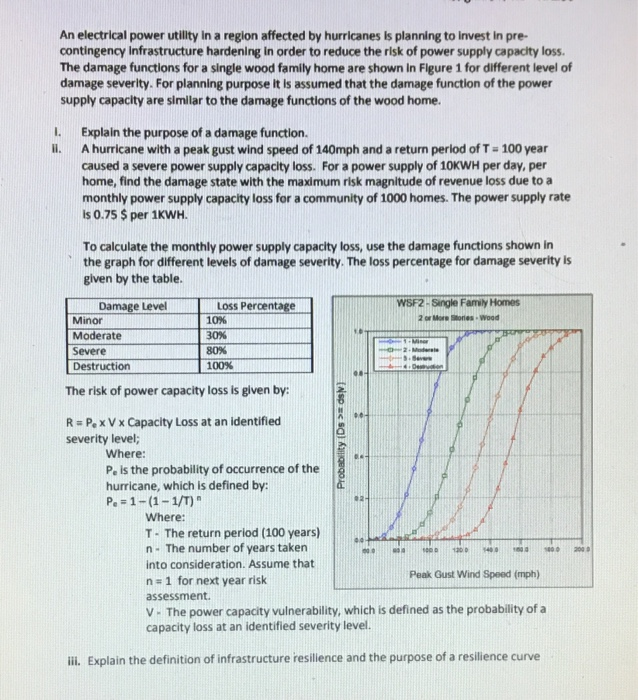

An Electrical Power Utility In A Region Affected By Chegg Com

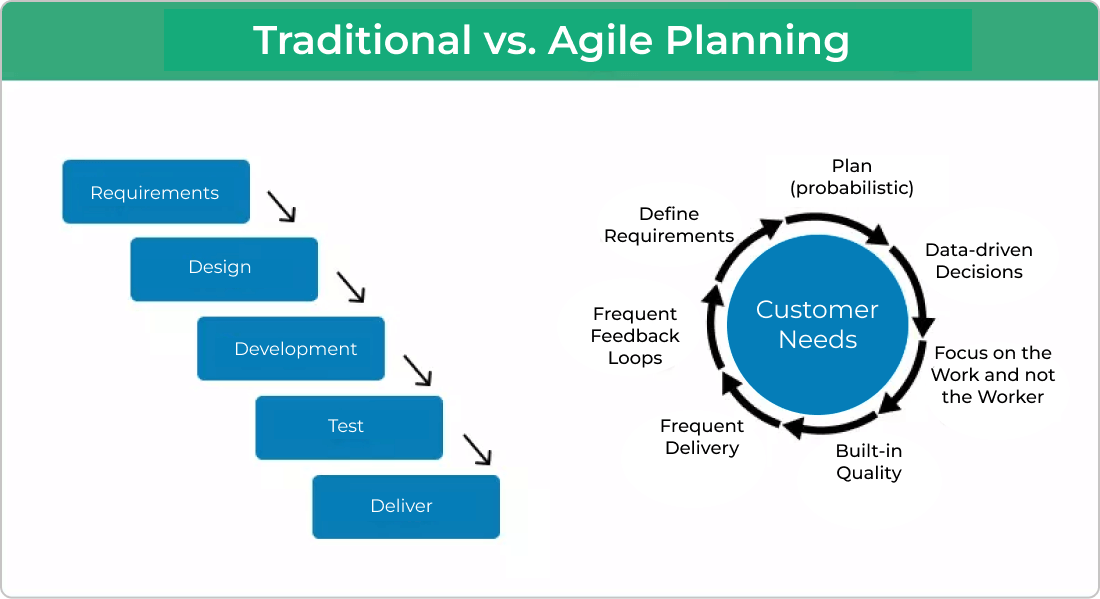

The Complete Beginners Guide To Agile Project Planning

1 The Two Levels Of Insurance Definitions Key Factors Underlying The Download Scientific Diagram

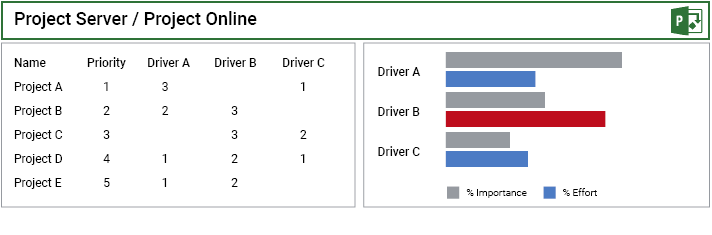

Ppm 101 Assess Portfolio Maturity In Order To Get There Acuity Ppm

Lecture 15 Chapter 11 Capacity Planning And Control Introduction Studocu

Service Level Agreement Methodology Download Scientific Diagram

Chapter 6 Demand Management Dp C Chapter 6 Ppt Download

Pi Planning Scaled Agile Framework

What Is Sales And Operations Planning S Op Plex Demandcaster

Module 5 Capacity Planning Pdf Inventory Operations Management

What Is Aggregate Planning 3 Strategies And Examples

1

Capacity Planning 3 Methods How To Implement Them Optimoroute

1

Inventory Management 101 The Master Production Schedule Mps Explained Optipro Software

Capacity Building Wikipedia

Solved An Electrical Power Utility In A Region Affected By Chegg Com

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

What Is Resource Management And Why Is It Important Planview

Iso Iec 000 1 18 En Information Technology Service Management Part 1 Service Management System Requirements

Capacity Planning And Management 2

Automotiveip Co Uk

Capacity Planning Strategies Benefits And Best Practices

What Is Material Requirements Planning Mrp

Chapter 7 Capacity Planning And Management Ppt Download

Data Model And Hierarchy Targetprocess Enterprise Agility Solution

3 Types Of Capacity Planning Strategies Valq

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Guidance For Implementing Covid 19 Prevention Strategies In The Context Of Varying Community Transmission Levels And Vaccination Coverage Mmwr

Capacity Definition In Lte As Operator Level Teletopix Org

Define Capacity Explain What Is Meant By Capacity Planning

It Management Processes Ibm Model Download Table

Importance Of

Capacity Planning Operation Management Definition Types Steps Benefits With Example In Hindi Youtube

Capacity Planning Meaning Strategies Importance And Procedure

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Capacity Requirements Planning Bit 3414 Operations Supply Chain Mgt Docsity

Aggregate Planning In A Supply Chain Members Samson Akyoo 1100 Ernest Mbezi 1129 Gladys G Yambesi 1151 Mwete Amisi Ali 1152 Anzuruni B Malisawa Ppt Download

Strategic Capacity Planning Based On Slides For Chase Acquilano And Jacobs Operations Management Mcgraw Hill Ppt Download

Production Planning Wikipedia

Capacity Planning And Control Ppt Download

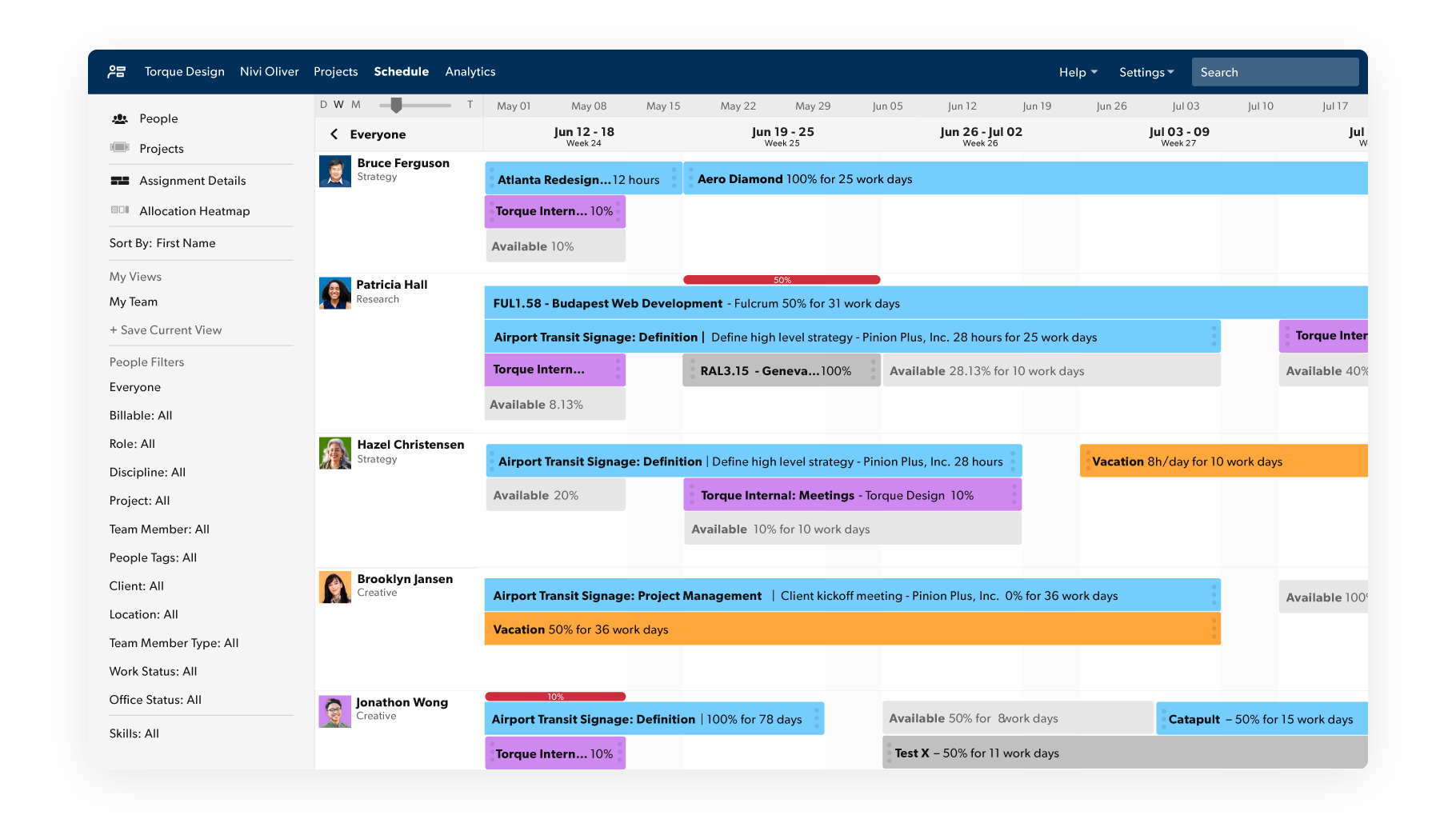

Capacity Planning For Project Managers How To Plan Your Team S Time

3 Types Of Capacity Planning Strategies Valq

Capacity Planning Everything You Need To Know Opensense Labs

Level Capacity Plan Level Capacity Plan The Inventory Size Is Varied Keeping The Operation Management

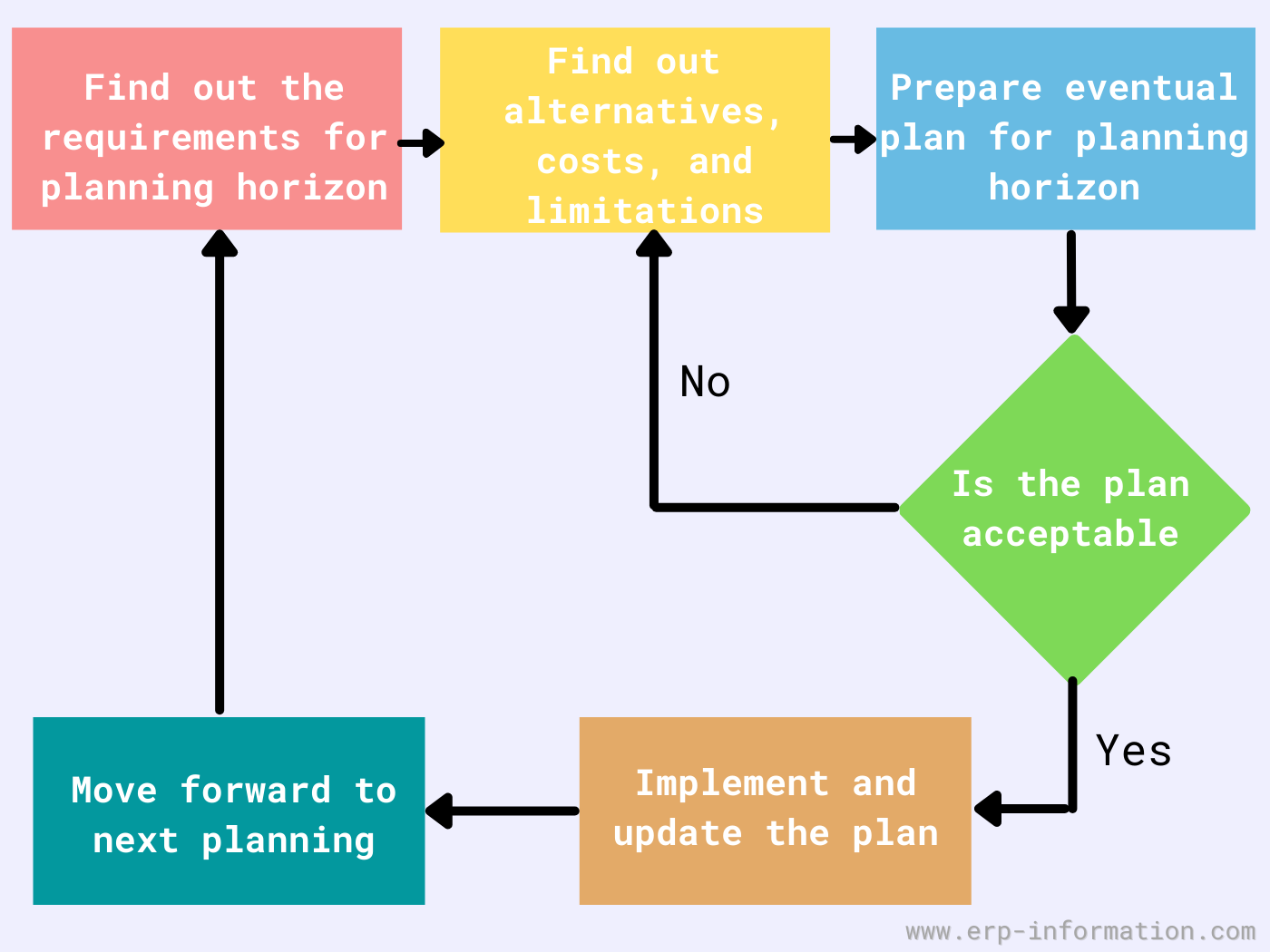

Demand And Capacity Management Decision Steps Download Scientific Diagram

Capacity Planning Meaning Strategies Importance And Procedure

What Is Aggregate Planning 3 Strategies And Examples

Omtqm Module Midterm Topic 3 Capacity Planning V3 Course Operations Management And Total Quality Studocu

Strategic Capacity Planning Defined Ppt Video Online Download

What Is Aggregate Planning 3 Strategies And Examples

Capacity Planning How Much Long Range Capacity Is Needed When More Capacity Is Needed Where Facilities Should Be Located Location How Facilities Should Ppt Download

Capacity Planning 3 Methods How To Implement Them Optimoroute

What Is Master Production Schedule Mps Definition Functions 6 Benefits

Capacity Management

Capacity Planning 3 Methods How To Implement Them Optimoroute

3 Types Of Capacity Planning Strategies Valq

3

Production Planning Wikipedia

0 件のコメント:

コメントを投稿